Raw materials are the foundation of finished products. Therefore, we apply a comprehensive set of ISO 9001 compliant supplier management systems for raw materials. Patpet judges the suitability of all materials in advance and selects the ones that pass our strict standards of quality and safety.

To maintain the excellent and consistent training collar quality, all the raw material suppliers are categorized based on performance and material quality.

Patpet goes through intensive quality control procedures from start to finish. This helps us provide our customers with the finest dog bark control and training collar quality products. Here are the IQC steps we follow.

It involves inspecting the incoming material whether they meet the inspection standards or not. Our inspection workers fill the inspection report and separate the defective material in different lots in storage for further inspection.

Workers forward the assessment report to the quality team for further authentication. The defective and incompetent materials are dealt with immediately and returned to the supplier for replacement within 48 hours.

Our expert team looks at the nature of quality problems. Then mark the raw materials as Passed or Rejected based on quality assessment reporting and communicate it back to the suppliers and add to inspection records.

After the strict examination of each incoming batch of raw materials, inspection results are placed on the system for faster processing and the inventory warehouse is distributed into the ERP System.

Each batch of materials and products is inspected as per our sampling plan, with control samples regularly checked for quality. Our quality expert selects material at random for inspection to identify and eliminate defects.

Constant monitoring of materials and production ensures that the quality of our finished products consistently meets the industry standards and specifications.

Patpet’s dog collar manufacturing facility runs a series of stringent tests. All our training and bark control collars undergo a series of more than 43 tests including the ESD static and drop tests. The tests ensure that all our products satisfy your target demographics’ expectations.

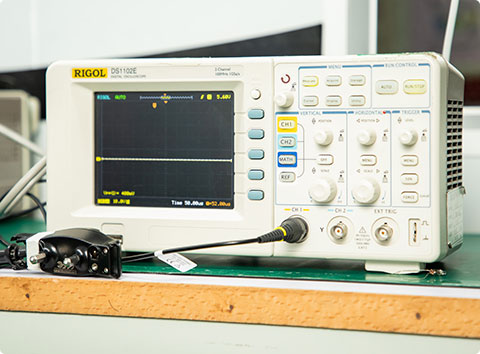

Patpet is committed to high-end production with great R & D input. It requires us to invest in cutting-edge machinery that aids in producing high-quality products that meet our customer’s needs.

We utilize the latest laser carvers, battery comprehensive tester, oscilloscope, and other machines to optimize the manufacturing and testing of our dog training products. Investing in state-of-the-art equipment enables us to produce more than 500,000 pieces of quality collars per year.

Patpet is committed to providing its customers with the best dog and bark control collars. We comprehensively inspect and test the quality of all our products to ensure that the appearance, functionality, and packaging are as per the industry standards. Here is a rundown of the inspections we do.

The appearance of each finished product is checked for irregularities and deformities to guarantee the visual appeal of our dog collars. Some of the details our team checks are:

Upholding high standards for our dog training products means they must function as meant with every use. To make sure our collars are up to industry standards, we check:

The packaging is the first aspect of the product your customers see, so it needs to signal quality upfront. Also, proper packaging protects the contents. Before shipping the products, we check:

Patpet’s commitment to rigorous quality standards, from raw material selection to processing and quality control to packaging, we offer dog and bark control collars that fulfill the need of the market.

Our stringent quality control methods have helped us maintain a refund rate of 2%, which is relatively lower than the 5%-6% that the industry currently experiences.

Need an expert? Our team helps you optimize your retail business and maximize your profits.